Home

Problem: Small wellness clinics and retail stores are stocking whole food supplements, homeopathy products and herbal remedies on book shelves, and they are all doing it without any product lane management containers like "bin boxes" or comparable with integral lane labeling and that dramatically slows down and confuses all aspects of inventory management, inventory control, and very accurate manual reorder processes.

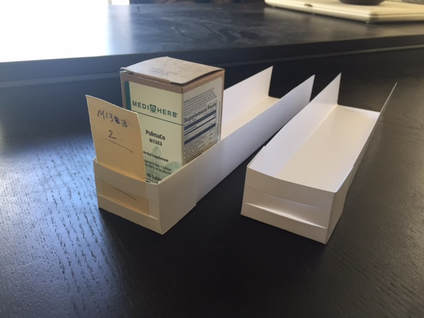

Solution: The image to the right shows inexpensive paper product channels with labeling attached. This provides an amazing amount of obvious and subtle benefits to stocking customers and product re-sellers.

While the product channels at right are just a proof of concept with plain old office paper, we want to be sure you realize this isn't just a retail hack nor an over-organization scheme.

There is an inventory management methodology referred to as 'Kanban', and this simple product channel with integral lane labeling aligns itself with Kanban and inventory management Best Practices that have been formally recognized since the 1950s.

While the product channels at right are just a proof of concept with plain old office paper, we want to be sure you realize this isn't just a retail hack nor an over-organization scheme.

There is an inventory management methodology referred to as 'Kanban', and this simple product channel with integral lane labeling aligns itself with Kanban and inventory management Best Practices that have been formally recognized since the 1950s.

- "Kanban is a Japanese term: ‘kan’ means ‘visual’ and ‘ban’ means card, so roughly translated, it means ‘card you can see."

- Kanban cards are cards that are used to manage inventory for Just-In-Time inventory systems in some of the largest companies in the world

- Our product lanes enable the attachment of a Kanban card to the front of the product lane for realizing the full benefits of this type of system

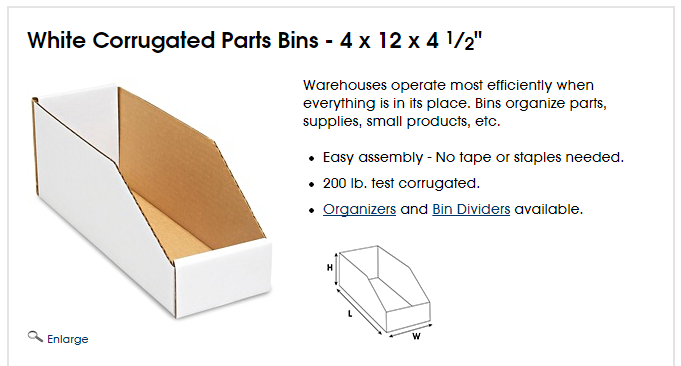

Bin Boxes - The inspiration for our "Product Channels"

https://www.uline.com/Product/Detail/S-704/Corrugated-Bins/White-Corrugated-Parts-Bins-4-x-12-x-4-1-2?pricode=WB0214&gadtype=pla&id=S-704Q3&gclid=CPHrvJqT59QCFROXfgodaqoHXg&gclsrc=aw.ds

https://www.uline.com/Product/Detail/S-704/Corrugated-Bins/White-Corrugated-Parts-Bins-4-x-12-x-4-1-2?pricode=WB0214&gadtype=pla&id=S-704Q3&gclid=CPHrvJqT59QCFROXfgodaqoHXg&gclsrc=aw.ds

For those in inventory management and the packaging industry, our solution is most comparable in concept and use to "bin boxes".

Bin boxes are generally thought of as something that holds a lot of items in an unorganized fashion, and our product channels with a front end cap are designed to hold material in single file line -- but the concept and the benefits or our channels are the same as those sought with Bin Boxes.

Bin boxes are generally thought of as something that holds a lot of items in an unorganized fashion, and our product channels with a front end cap are designed to hold material in single file line -- but the concept and the benefits or our channels are the same as those sought with Bin Boxes.

Our Product Channels with Integral Lane Labeling System

This image shows a product channel that is 2" wide x 10.5" long x 1.5" tall. The two slits in the front enable the use of a removable Kanban card. These are two of our prototypes that require glue dots or other adhesive for assembly. We are also pursuing a design that has a roll-end tray style front that would fold into shape without adhesive.

The channel widths we are considering now include:

1.5", 2", 2.25", 2.5", 2.75", 3.25", 4". The final standard length will likely be 10.5" but that is yet to be determined. We will also be offering pre-cut Kanban cards in a few sizes and some may be die cut if we use the roll end tray style boxes.

Our offerings will always consist of Hand Made products made in the USA!!

The ideal solution consists of fully pre-assembled (glued), collapsing paper boxes (beers 4 corner) that would look like these when expanded -- unfortunately, those products require die-cutting, gluing, and very large orders to make it economical; and the problem with that is that these need to be thought of as one time purchase items and once our target market is saturated, the re-order rates will be very, very low, and thus we need a design that enables us to produce on a much smaller batch size -- and that's where the roll-end tray boxes and the boxes that customers assembles with glue dots came in.

For lowest demand sizes, we may never in fact offer anything other than those needing glue dots a they can in fact be hand made in very low quantities. There is more on all of this in the "Production Dilemma" section below.

The channel widths we are considering now include:

1.5", 2", 2.25", 2.5", 2.75", 3.25", 4". The final standard length will likely be 10.5" but that is yet to be determined. We will also be offering pre-cut Kanban cards in a few sizes and some may be die cut if we use the roll end tray style boxes.

Our offerings will always consist of Hand Made products made in the USA!!

The ideal solution consists of fully pre-assembled (glued), collapsing paper boxes (beers 4 corner) that would look like these when expanded -- unfortunately, those products require die-cutting, gluing, and very large orders to make it economical; and the problem with that is that these need to be thought of as one time purchase items and once our target market is saturated, the re-order rates will be very, very low, and thus we need a design that enables us to produce on a much smaller batch size -- and that's where the roll-end tray boxes and the boxes that customers assembles with glue dots came in.

For lowest demand sizes, we may never in fact offer anything other than those needing glue dots a they can in fact be hand made in very low quantities. There is more on all of this in the "Production Dilemma" section below.

The Inventory Stocking Problem In More Detail -- A Case Study in Organization and Efficiency

The image on the right is a "small" wellness provider who is carrying over 300 unique items. This vendor sells approximately $50,000 per year in products from this inventory and he places stocking orders to replenish his stock one time per week.

The majority of products shown in this image come from only two vendors, but there are in fact a total of approximately 8 different product lines from those 2 vendors -- meaning there are 8 different start and end spots for keeping products in numerical order in conjunction with vendor order sheets. The products themselves come in 7 different widths that range from 1.5" to 3.25" wide with the majority of those shown here being 2" wide.

The majority of products shown in this image come from only two vendors, but there are in fact a total of approximately 8 different product lines from those 2 vendors -- meaning there are 8 different start and end spots for keeping products in numerical order in conjunction with vendor order sheets. The products themselves come in 7 different widths that range from 1.5" to 3.25" wide with the majority of those shown here being 2" wide.

His starting point was without product channels and without product lane labeling (and without bookshelves, but that's a different story) -For many years this stocking customer stocked product without any type of product channels or product lane labeling. He also had no automated Point of Sale system that would track his sales that would have made incremental stock replenishment orders easier, and he didn't track the items as they came out of inventory either, so he had no way to easily place his weekly restock orders. He had a spreadsheet that had all the items on it with minimum stocking quantities, and he and a helper would do inventory 1 time per week. The person with the clipboard would read out the part number and minimum order amount and the person with eyes on the products would reply back with either "good" or the number that needed to be ordered. The problems with this system were numerous.

- He didn't stock "all the products". He was keeping his spreadsheet list up to date as he added and removed products from his desired inventory. He could have used a full list of all the products and just skipped the ones he didn't stock and that was one of the first changes he made. With that change he didn't have to reprint his list as much, but when he did, he was printing more pages than he needed.

- Until the clipboard person and the watcher got in synch (usually after calling out and responding to 20 or thirty products), there was a lot of confusion and backtracking.

- They would often times have to break half way through to clear their heads.

- Errors were plentiful.

- If the helper was not there, the inventory counting time tripled and the errors went up significantly as the eyes went back and forth from the sheet to the unmarked product lanes.

Improvement #1 -- Masking tape on the edge of the shelf -- A Kanban Card System of sorts -- The first attempt at an efficiency increase involved putting masking tape on the edge of the shelves and writing the product code and the desired stocking amount in front of the product lane. This worked wonders. The person with eyes on the product would look at the desired quantity, and if didn't match, he'd yell out the part number and the quantity he wanted to order. Likewise, if the helper was not there, he could note it quickly on his spreadsheet. This dramatically shortened the time for visual inventory and it eliminated the need for a second person to be more efficient.

New Problem #1 -- Inventory shifts -- What happened when he added an inventory item that was supposed to go between two other products from a numerical perspective? Items were pushed right. Product lanes got disorganized with the push and each individual product typically had to be touched to get all the soldiers in line again. But worse yet, products at the end of the shelf had to move down to the next shelf and that would displace other products on that shelf and that would domino to the end of that product line. Oy vey. And now that he had tape with lane labeling, not only did the products need to move, so did the tape too!?! Tear the tape, move it to the right, cut off the pricing at the end of the shelf and move it down, but that pricing below needed to shift to the right and... Oy vey. Oh, and don't forget to put a small piece of tape in where the new product goes -- breathe. relax. -- and do this again every few months as his desired stock changed or as his vendors modified the size options of their offerings...

Improvement #3 -- Product Channels with an end cap -- After a few hours of futzing around, it finally dawned on us that we needed the equivalent of boxes for these items. We took paper, folded it up, taped it together and we produced our first product channels with integral end caps. We went into Google Sheets and devised a program to create a list of labels from our master product list. We printed that out. We cut those labels into the small squares that they were intended to be. We taped those to our newly formed product channels with endcaps and we had landed on a Kanban card systems that was pretty darn good.

Obviously, the paper isn't great for making shifts to the next shelf but if there's less than 4 items in the channel, it's doable.

Obviously, the paper isn't great for making shifts to the next shelf but if there's less than 4 items in the channel, it's doable.

Improvement #4 -- Prototype a system with Manilla folders -- Our next version was done with Manilla folder material. We just made enough prototypes to make sure that could be an inexpensive do it yourself solution, and it works just fine. This would still require a two handed move from shelf to shelf as the Manilla isn't stiff enough for a one handed move, but that's really not that big of a deal. If you want to do this, all you need is a manual paper shearer. You can shear about 7-10 sheets at a time. Cut them to your desired width adn length. Bend them. Then take some of the bent ones and shear those for end caps. Use a stapler or scotch tape and you are almost home.

Improvement #5 -- Commercially produced product channels with end caps -- As of 10/5/2017 our working prototypes have been designed and final material selection is in process.

The end caps on these are not a separate piece as was the case in improvement #4. One large rectangular piece of commercial paper is scored and cut so it can be folded into shape.

The end caps on these are not a separate piece as was the case in improvement #4. One large rectangular piece of commercial paper is scored and cut so it can be folded into shape.

Listing End User "Buts" and "Butt Responses" often times helps realize benefits to a greater degree...

Sometimes it's hard to recognize benefits and value until you experience something. This is no different. Some folks will see the benefits of this right away and others won't. Below are things that end users who are not wired for operational organization might say, along with the responses that should help them cognitive realize the benefits they are missing.

"My inventory sizes and shapes never change, so the benefits of quick inventory moves isn't a benefit" -- I don't know who you buy from, but that is a rarity.

"But I have a digital Point of Sale system that tracks all my sales for me, and I just use that for reorders" -- That doesn't help at all with the product shifting that can transpire on a regular basis. And what about when you want to increase the stock you are holding? What about when you need to do a monthly or quarterly inventory to make sure you aren't losing inventory "somehow". What about when you add new items?

"But I just don't see why I need the minimum stocking level on the KanBan cards" -- You need it somewhere, why wouldn't you put it in the same place your eyes need to go to check your current inventory?

"But I don't stock that many products, it's not that big of a deal to me" -- I've seen folks with as little at 20 products on their shelf sell their last item -- and without some type of lane labeling, they are going to exert mental energy holding and finding that shelf space again when the products come in. Not a big deal, right? No.. it's not... but if you do this a few dozen times with not only these items but all of your other office items, it all adds up to a mental quagmire that most will admit too once you ask them about their office organization skills.

Think of these boxes like salt or pepper. A most basic seasoning. Few people eat salt and pepper straight up -- but few would challenge the fact that those simple and subtle adders can dramatically change the taste of food for the better.

"My inventory sizes and shapes never change, so the benefits of quick inventory moves isn't a benefit" -- I don't know who you buy from, but that is a rarity.

"But I have a digital Point of Sale system that tracks all my sales for me, and I just use that for reorders" -- That doesn't help at all with the product shifting that can transpire on a regular basis. And what about when you want to increase the stock you are holding? What about when you need to do a monthly or quarterly inventory to make sure you aren't losing inventory "somehow". What about when you add new items?

"But I just don't see why I need the minimum stocking level on the KanBan cards" -- You need it somewhere, why wouldn't you put it in the same place your eyes need to go to check your current inventory?

"But I don't stock that many products, it's not that big of a deal to me" -- I've seen folks with as little at 20 products on their shelf sell their last item -- and without some type of lane labeling, they are going to exert mental energy holding and finding that shelf space again when the products come in. Not a big deal, right? No.. it's not... but if you do this a few dozen times with not only these items but all of your other office items, it all adds up to a mental quagmire that most will admit too once you ask them about their office organization skills.

Think of these boxes like salt or pepper. A most basic seasoning. Few people eat salt and pepper straight up -- but few would challenge the fact that those simple and subtle adders can dramatically change the taste of food for the better.

Our Production Dillema

We are facing the same dilemma that all producers of a new product face with an added twist that deters most "smart businessmen" from engaging in this type of business endeavor -- the big problem here is that generally speaking, this is a low cost, one time sale item, in a very niche market, with a lot of sizes and varying customer needs with regards to length.

- This is a one time sale. Nobody should need to "replace" this item and if they do it will likely be many years from now -- and if it doesn't hold up as it should, we'll need to up the quality so it lasts as it should!

- One size does NOT fit all. In this small office alone there are 7 different width products. If this is done with a die, we need a die for each width and the upfront costs mean we need to put more time into screening and choosing initial vendors. This also can make it more difficult to negotiate pricing as volumes rise and fall.

- Orders from some new end users will be large. What's large? Maybe 400 channels or so. That's not a bad thing, but remember these items are not that expensive.

- Orders from other new end users will be small. For the folks who just started stocking, they may only have 5 to 20 skus on their shelves. The shipping may be as much or more than their order, and that's assuming we decide to sell single pieces, which is very, very inefficient for us. If we don't sell single pieces, orders will be larger, but customers will be stuck buying 10 to 25 of each size they need, not know if they'll ever need all those items they are buying...

- Subsequent orders from end users will be incremental and very small -- Once we get the majority of the stocking customers around the world up to speed, they will only need to order from us again when they add new products or new product lines and those folks will typically take on product lines just a few products at a time.

Our Marketing Dillema

Given the items above, and knowing this likely isn't a viable, long term, stand alone business, and knowing sales will peak and drop in a very short period of time, it is going to be very important we setup our distribution system to minimize our individual, small order shipping involvement. There is no reason to scale up for shipping handling for end customers when you know scaling down is just around the corner.

Our Marketing Plan - The Product Manufacturers are the only way to go...

Our first line of distribution must be via the Product Manufacturers themselves, and this naturally makes sense for a lot of reasons...

Manufacturer Giveaways -- Ideally, these items are in fact so important that the manufacturers of the products that the stocking customers are stocking should "give these away" to their stocking customers, and that is going to be our first goal.

Manufacturers pass our products along at cost or at cost plus -- For manufacturers that don't want to give them away, they would have the opportunity to sell them to their customers.

Manufacturers sell our products to their customers for profit - Manufacturers decide to sell our products to their customers with marquee pricing or some other multiplier.

We are likely going to offer price breaks to manufacturers for offering these items for free or at cost plus. Our goal is not only to make a few pennies on this venture -- it is to make these stocking customers better business people, one office at a time.

Manufacturer Giveaways -- Ideally, these items are in fact so important that the manufacturers of the products that the stocking customers are stocking should "give these away" to their stocking customers, and that is going to be our first goal.

Manufacturers pass our products along at cost or at cost plus -- For manufacturers that don't want to give them away, they would have the opportunity to sell them to their customers.

Manufacturers sell our products to their customers for profit - Manufacturers decide to sell our products to their customers with marquee pricing or some other multiplier.

We are likely going to offer price breaks to manufacturers for offering these items for free or at cost plus. Our goal is not only to make a few pennies on this venture -- it is to make these stocking customers better business people, one office at a time.